Farm inspection

BIOfouling

Precise BIOfouling location heat maps, stage identification, and spread rate prediction from fish farm cage inspection videos

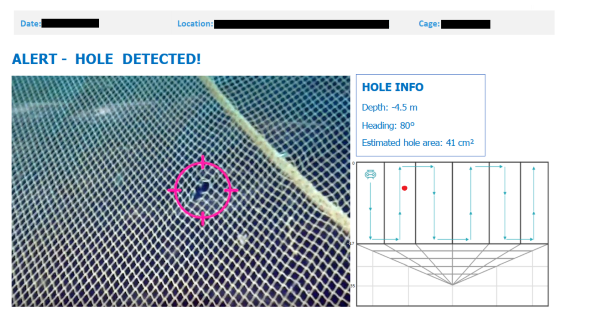

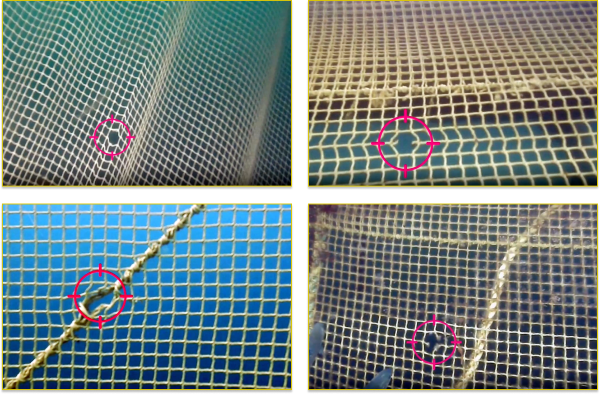

HOLE detection

We automatically detect holes in fish farm nets from ROV video, providing precise locations and real-time alerts.

BIOfouling

Precise BIOfouling location heat maps, stage identification, and spread rate prediction from fish farm cage inspection videos

BIOfouling solution analyzes cage videos recorded by any camera/ROV with our fully automated AI and ML tools, providing three innovative features that allow you to manage BIOfouling on your pen nets at lower costs and with better results:

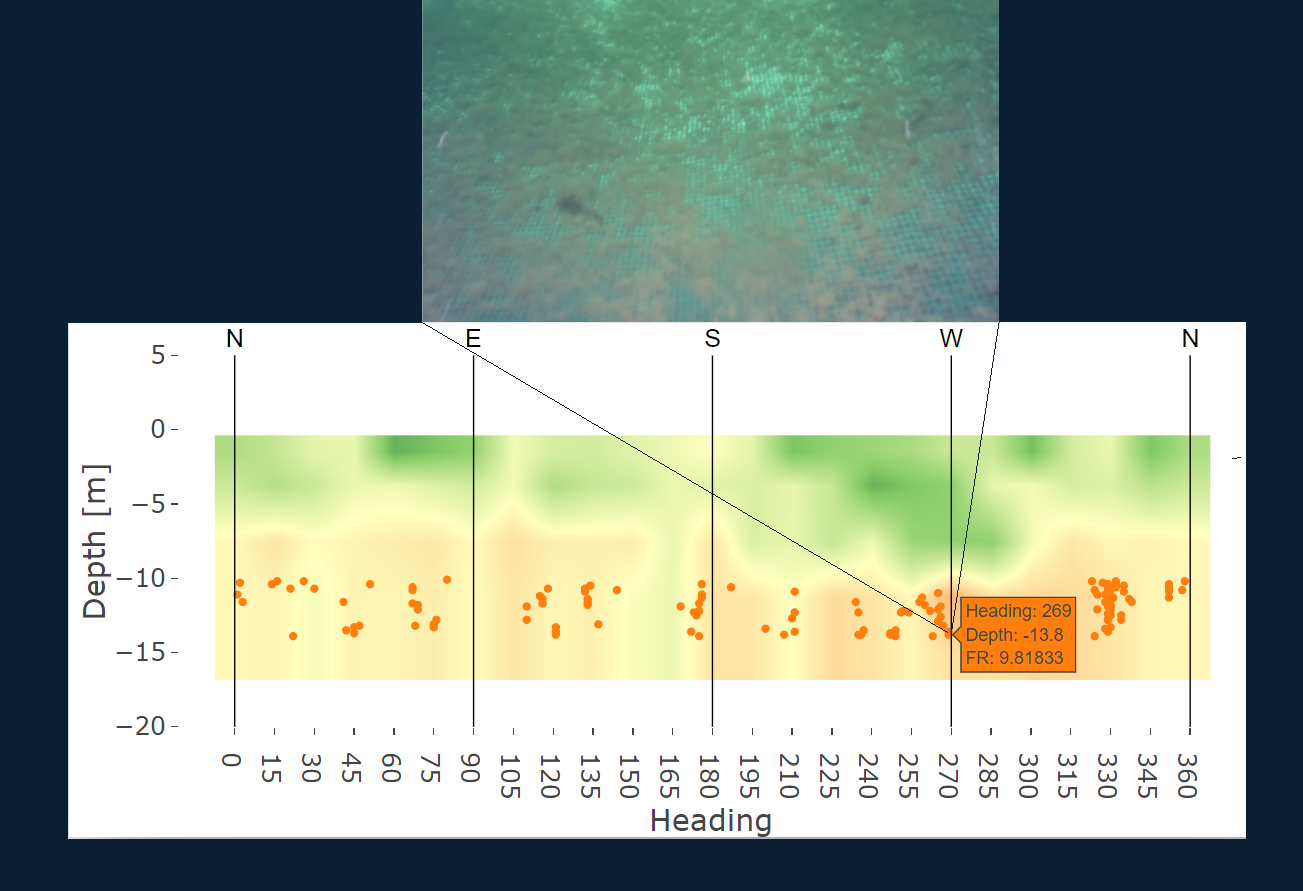

• The precise location of BIOfouling (heatmap)

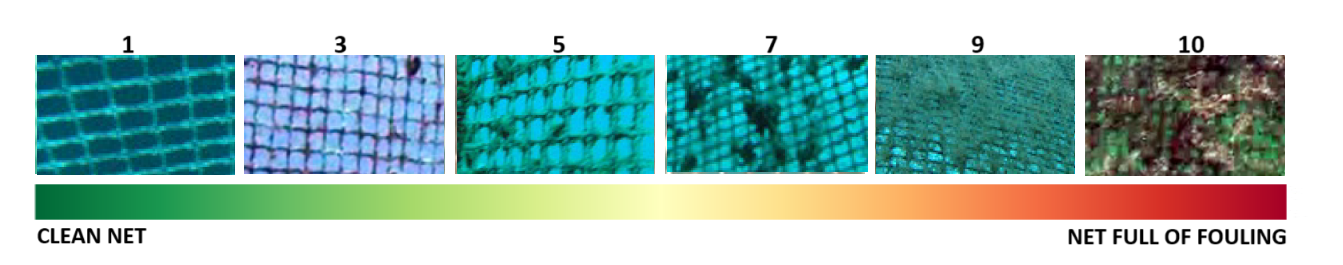

• BIOfouling stage identification (Scale 1Q10)

• AIQbased spreading rate prediction

The BIOfouling ratio is a metric that indicates ten stages of net cleanliness. Green areas signify a clean net, while red regions (stages 9 or 10) represent areas with significant BIOfouling.

The BIOfouling rate strongly correlates with dissolved oxygen levels in the cage.

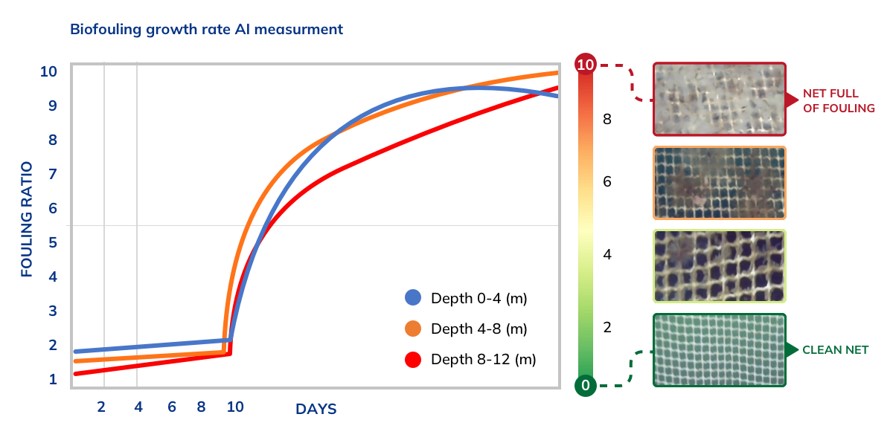

FOULING GROWTH GRAPH – TRACK AND PREDICT SPREADING

Regular monitoring generates data to create fouling spreading graphs, which help predict when fouling will spread exponentially. The graph hows a “knee” or “elbow” in the growth curve, indicating the point at which growth due to reproduction becomes exponential.

We also deliver an interactive map showing the largest BIOfouling ratio (FR) measures on the heat map, represented with original frames from the inspection video.

LESS COPPER RELEASE AND BETTER FISH HEALTH CONTRIBUTE TO YOUR ESG METRICS

Cleaning on a need basis reduces copper release, protecting sea beds and fish health.

Innovative BIOfouling management enhances the company’s sustainability in two key UN Sustainable Development Goals. This significantly contributes to the long-term sustainability of the aquaculture business and proves your ESG score.

How it works?

Hole Detection

We automatically detect holes in fish farm nets from ROV video, providing precise locations and real-time alerts.

We deliver the alert in the near real-time!

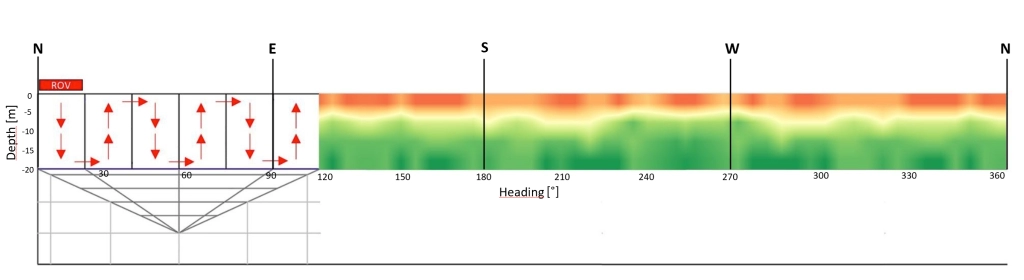

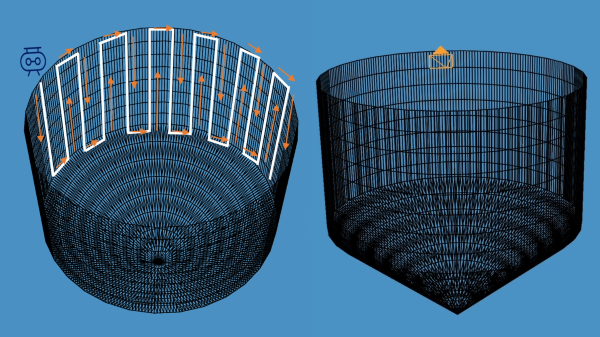

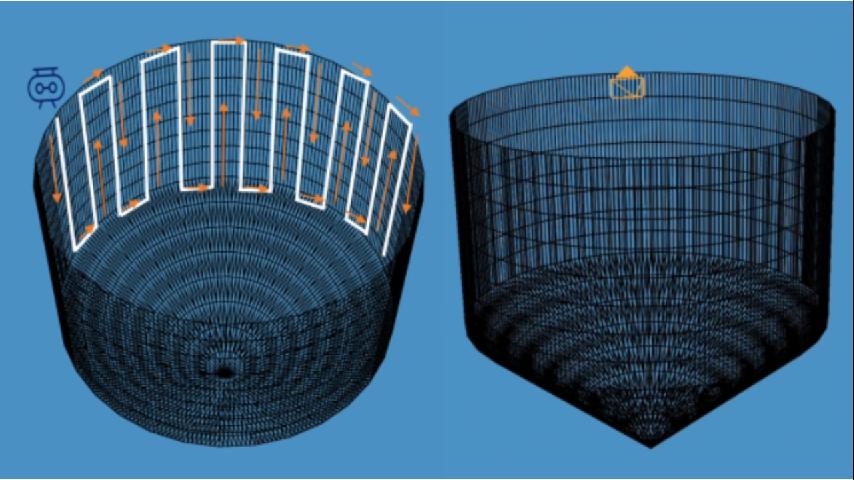

Our software follows a standard protocol for inspecting round and square fish farm cages for holes. Our solution works with any ROV measuring depth and heading, mapping the entire cage surface. The goal of any ROV inspection operator is to leave no areas uninspected.

Our advanced system automatically detects holes in pen cage nets recorded with any ROV or camera, providing precise locations for your divers to ensure timely repairs. By identifying and addressing holes before they become large enough to allow fish to escape, we help you maintain the integrity of your cage infrastructure and ensure the safety of your fish.

Our solution offers several key benefits:

1. Accurate Detection: Our system utilizes state-of-the-art AI and ML algorithms to identify even the smallest holes in the netting, ensuring no potential escape points are missed.

2. Precise Localization: Detailed mapping based on the reconstruction of the set path for the ROV operator precisely estimates the hole locations and allows divers to find and fix the issues, minimizing downtime and labor costs quickly and efficiently.

3. Preventative Maintenance: Early detection and repair prevent small holes from growing larger, reducing the risk of fish loss and maintaining stock levels.

How it works?

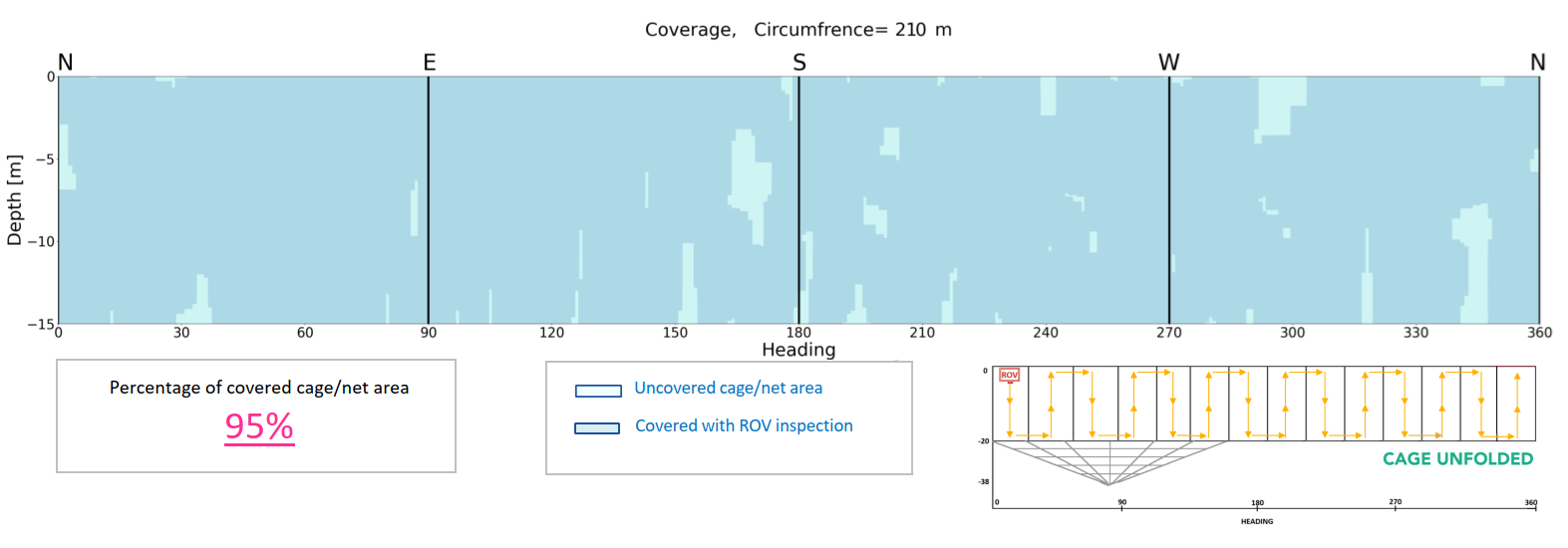

100% inspection

Our solution shows how good ROV inspection is covering the entire pen net on video

Our solution for spatial positioning of the video frames ensures comprehensive inspection by verifying that the inspection camera (ROV) has covered the entire surface of the cage. This guarantees that all parts of the cages are properly video recorded, ensuring the accuracy and reliability of your reports.

We measure and demonstrate the ROV’s complete field of view coverage in inspection videos, guaranteeing all parts of the fish cage are properly recorded and ensuring the accuracy and reliability of your hole detection and other reports.

Our software follows a standard protocol for inspecting round and square fish farm cages for holes. Our solution works with any ROV measuring depth and heading, mapping the entire cage surface. The goal of any ROV inspection operator is to leave no areas uninspected.

Complete Surface Coverage:

Our software checks that the inspection camera has captured the entire cage surface, leaving no areas uninspected.

Key features include:

- Reliable Monitoring: Reducing the risk of undetected issues enables timely and precise interventions.

- Enhanced Accuracy: By ensuring your ROV operator recorded the full cage coverage, you can evaluate and reward operators who achieve high accuracy, providing a true and precise representation of the cage condition.